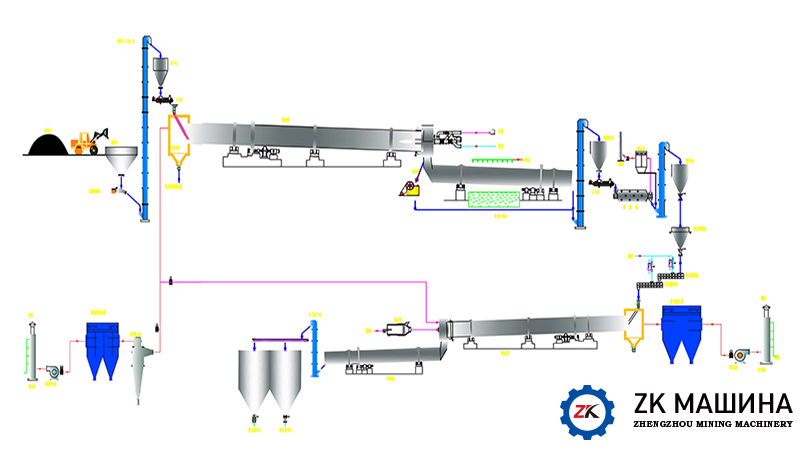

Product Description:

Our company has configured a production line for roasting and

acidizing lithium ore with lepidolite, spodumene and other raw

materials, which has received positive recognition from users due

to its excellent performance, stable production condition and easy

operation.

What's more, the kiln is advancedly equipped with a wireless

temperature monitoring system and a remote intelligent variable

speed kiln condition control system, which makes it convenient for

the personnel to adjust the kiln condition in real time.

In addition, with the production line, the raw material crystal

conversion rate is high, the acidification is complete, and the

lithium leaching rate and lithium recovery rate are 15% higher than

the traditional process.

Features:

The production line is able to operate with high stability. A

wireless temperature measurement and monitoring system is applied

to ensure that all working parameters run more efficiently as well

as accurately. It is able to strengthen heat recovery to reduce

energy consumption with economic efficiency. Moreover, the

newly-installed dust removal device works with great efficiency

while keep the construction cost within a budget.

Technical Parameters:

Spodumene as Raw Material (Without Production of Other Products )

The raw material used is spodumene without the production of other

products. The following is a table of the annual output, amount,

and main equipment models.

| Final Products | Annual Output(t/a) | Spodumene Amount(t/h) | Main Equipment Model |

|---|

| Conversion Process | 5000 | 5-6 | Roasting Kiln:φ2.8×50m; Cooler: φ2.6×40m |

| Acidification Process | 10000 | 10-12 | Roasting Kiln:φ3.5×60m; Cooler: φ2.4×40m |

| Acidification Kiln:φ3.5×50m; Cooler: φ2.4×40m |

| Ball Mill:φ1.83×6.4m |

Lepidolite as Raw Material

The raw material used is lepidolite with an estimated 60% of

lepidolite. The table below shows the annual output of lithium and

the main equipment models.

| Final Product | Annual Output of Lithium(t/a) | Amount of Mixed Raw Materials (about 60% of Lepidolite) (t/h) | Main Equipment Model |

|---|

| Rotary Kiln | 3000 | 15-18 | φ3.5×60m |

| Cooler | 5000 | 25-30 | φ4.2×72m |

| Acidification Kiln:φ3.5×50m; Cooler: φ2.4×40m |

| φ3×45m |

| Ball Mill:φ3.2×13m |

Applications:

Application: The production of lepidolite and spodumene raw

materials, such as roasting, acidification and cooling, can be

highly benefitted with this product. High performance in the

production stage can be easily achieved by using this product,

making it the perfect choice.

It can work greatly under intense heat or cold temperatures, which

makes it a very flexible and reliable product. It's easy to use and

it gives you the precise results you need in the shortest amount of

time, so you can get back to work quickly and efficiently.

With this product, all of your roasting, acidification, and cooling

needs for lepidolite and spodumene raw materials will be taken care

of, making this product the perfect choice for any production

process.

Support and Services:

We provide technical support and services for our Lithium Carbonate

Production Line.

Our team of experienced technicians can help you to install the

production line, set it up and provide technical assistance for the

operation and maintenance of the production line.

We also provide comprehensive after-sales services, such as

troubleshooting, on-site repairs, and training for your staff.

We are committed to providing the highest level of customer service

and satisfaction.

Packing and Shipping:

Packaging and Shipping for Lithium Carbonate Production Line

Our Lithium Carbonate Production Line is packaged and shipped with

utmost care to ensure that it reaches you in perfect condition. Our

team will take the utmost care to make sure that the product is

packed carefully and securely. We offer both local and

international shipping options.

Local Shipping

For local shipping, we use a leading delivery service provider that

offers secure and reliable delivery. The product will be delivered

to you within the estimated time frame.

International Shipping

For international shipping, we use a trusted shipping carrier with

a track record of providing reliable and secure service. We will

ensure that the product is packaged securely and shipped in a

timely manner.